VKT Wear Resistant Ceramics

Infinite Shield and Infinite Shield Light

Effective wear protection with VKT ceramic Infinite Shield and Infinite Shield Light.

The wear of machinery components caused by abrasion and / or corrosion represents a considerable cost in the operation of today's industrial plants.

The degree and rate of wear depends on many factors such as: conveying speed, throughput capacity, impact angle, operational temperature, form / shape of the bulk material. Also moisture content and chemically aggressive media can also have an influence. Furthermore, for existing plants, technical conditions are significant.

Infinite Shield can be applied in both new and / or existing installations. In general Infinite Shield wear protection can be applied onto high wear components which can be exchanged during maintenance works. Depending on the wear severity of the components Infinite Shield can be applied as complete or partial protection of the component; for example full face or just the tip and root face of a conveyor flight; it can be also applied to shafts or the edges of transition pieces.

Following the examples of nature

Our work in the field of environmental technology operates in a similar way to the natural world - effective, reliable and totally professional. Our customers are very important to us and therefore they will get the best service.

Armadillos

Head, body and tail of an armadillo are each formed by a leather-covered carapace which consists of many hexagonal horn- and bone plates, that are formed as a skin protection.

Turtles

The shell of turtles, constitutes at least 30% of the weight, consists of massive bone plates. It encloses all major organs and body regions.

Rhinos

Rhinos were given their names because of their thick skin that surrounds the animal as an armor.

Infinite Shield

Infinite Shield consists of ceramic elements which offer, because of their shape and size, many advantages. Due to the small size of the single elements and their optimized shape the contour of the component to be protected can be accurately followed. Thus the original form of the plant component will not be altered and its performance will be 100% maintained.

The ceramic elements will be bonded directly with a special bonding which is adapted to the environmental parameters. The direct bonding without any additional intermediate layer enables an optimum connection between component and ceramic elements.

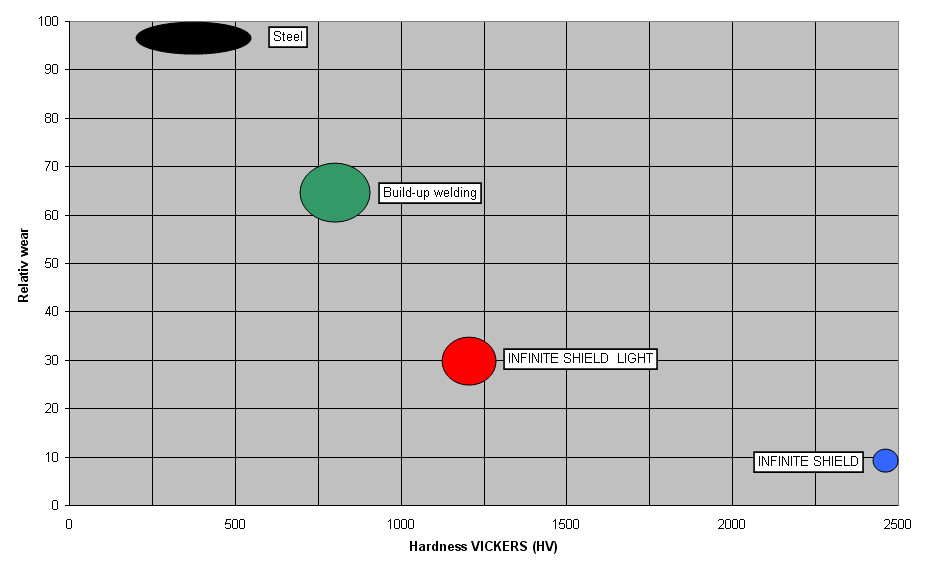

Due to the extreme hardness of 2500 Vickers HV, Infinite Shield is completely abrasion resistant to all media. It can only be worked on by diamond. For operating temperatures higher than 300 ° C, a mechanical fixture is used.

The ceramic material used for Infinite Shield is characterized by specific material properties and thus provides excellent wear protection.

Main advantages with using ceramics are:

Excellent wear resistance against abrassion.

Excellent wear resistance against corrosion.

Thermal stability.

High thermal conductivity.

Infinite Shield Light

Infinite Shield Light is a cost-effective alternative to Infinite Shield. It is harder and more abrasion-resistant compared to almost all metallic materials, while completely resistant to corrosion.

Bonding technology

Although the ceramic elements are the main wear resistance of Infinite Shield, a bonding process, suitable for different metallic materials had to be developed to bond the ceramic elements to the wear protected surfaces. This specifically developed bonding process is significantly important for the durability of the wear protection. The combination of the ceramic elements with the bonding process is what gives Infinite Shield its ability to withstand high mechanical, thermal and chemical stresses over a long period.

The bonding process is custom designed for the different fields of application. Factors like impact resistance, vibration, strain, corrosive environment, temperature have to be considered. The end result is a highly wear resistant ceramic element strongly bonded to a metallic surface without intermediate layers

Comparative analysis

Effective wear protection with VKT ceramic Infinite Shield and Infinite Shield Light - Your partner for wear protection.

Cost comparisons

Relative wear rates of different materials

Comparison of hardness for different materials

Fields of application

Wood-working industry

Cement industry

Energy production

Sewage treatment

Waste water treatmenrt

Constructional material industry

Mining

Advantages

Excellent wear resistance against abrassion.

Excellent wear resistance against corrosion.

Thermal stability.

High thermal conductivity.

Consists of hexagonal or rectangular ceramic elements.

Optimal contour adjustment to the component in need of protection.

Extreme hardness, therefore, absolutely resistant to abrasion.

Securely bonded up to 150°C, mechanically fixed over 150°C.

Permanent bonding using high-performance adhesive.

Applied without any gaps.