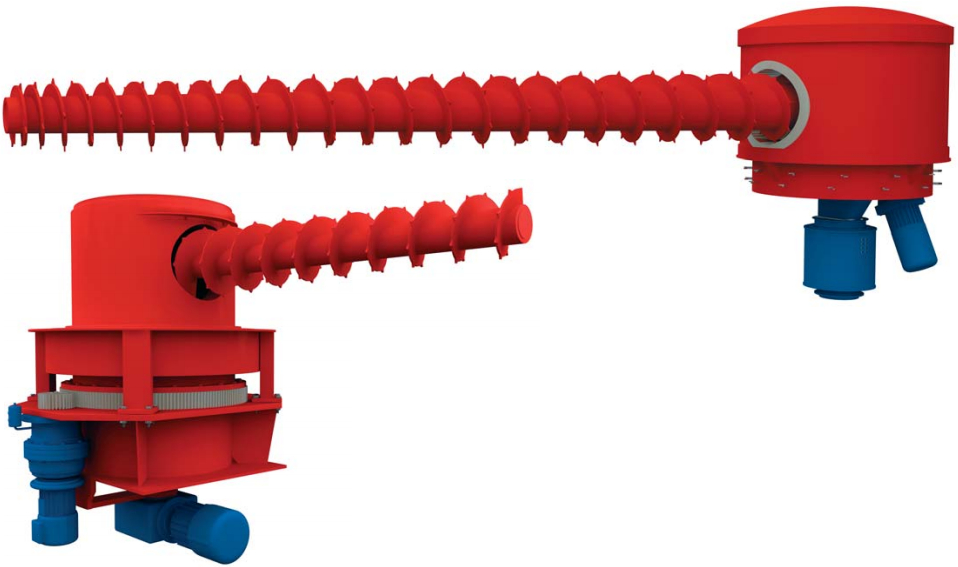

SHW Rotating Screw

Large rotating screw can be used for the discharge of bulk materials from different types of silos.

The discharge unit for dry / semi-dry difficult to handle bulk materials. The manufacture of screw is dependent on the bulk materials - scarifiers, screw pitch, construction size 1,450 mm diameter with two screws possible.

Component

Discharge Component

Applications

- Bulk material reception

- Bulk material intermediate storage

- Sawmills and particle board plants as well as in the cement industry and in heating and power stations.

- Concrete and steel cylindrical silos or in stock piles.

- Paper Waste:

- Fibrous, compacts / blocks

- Paper Sludge:

- Fibrous, compacts / blocks

- Dry Flakes:

- Compacts

- Sander Dusts:

- Compacts

- Wet Flakes:

- Compacts

- Shredded Waste Wood:

- Blocks, abrasive

- Wood Chips:

- Blocks, abrasive

- Bark:

- Compacts / blocks, abrasive, corrosive

- Secondary Fuels:

- Compacts / blocks, abrasive

- REA gypsum:

- Compacts

Photo Gallery

Technical Data

- Drive:

- 3 - 200 kW

- Weight:

- approx. 4 -24.6 t

- Dimensions:

- Silo:

- Up to ⌀ 8,000 mm, 12,000 mm, 15,000 mm, 25,000 mm

- Tower:

- Up to ⌀ 900 mm, 1,450 mm, 2,100 mm, 3,100 mm

- Unit:

- Screw adjusted to the bulk material

- Controls:

- Motor temperature, overfilling sensor, central lubrication

- Wear:

- As an option, specially tailored to the application and the bulk material, for example different stainless steels, Hardox, wear protection welding, Infinite Shield (ceramic)

- Execution:

- CE declaration of conformity

ATEX: standard no ex-qualification

Alternatives:

Inside: Zone 22 /

Outside: No Zone (EX II 3/-D)

Inside and Outside: Zone 22 (Ex II 3/3 D)

- Diameter of approx. 10 m up to 25 m.

- Discharge capacities of more than max. 400 m3/h.

- Solid construction (i. e. live ring for screw and tower).

- Regular discharge over the whole silo cross section realized by a conical progressive screw.

- Simple and quick erection of the installation on site by mainly pre-assembled groups of components.

- Good accessibility of the installation even during operation.

Technical Drawing

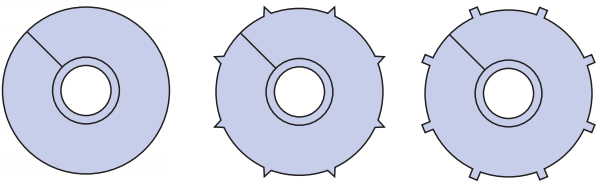

- The manufacture of the screw wings depends on the bulk material:

Design Characteristics

- Cantilever design

- Robust construction

- Cone screw axis

- Screw bearing independent of rotating tower bearing

- Wings with scarifiers

The rotating screw consists of a screw with a rotating tower, in which the screw is held and where the drive gear and the central lubrication systems are. The drive motor, advance drive, cooling and electrical switch cabinet are also rotating and arranged below the tower and are easily accessible.

The discharge screw consists of a conical tube with screw flights progressively inclined. Thus a regular discharge over the whole silo cross section is guaranteed. Dependent on the bulk material, the flights are equipped with scarifiers.

The cover is rotating and connected via a slide bearing to the tower. The whole tower rests on a ball bearing slewing rim, whose exterior ring is screwed fix below the silo bottom with the cast iron ring.

The load-dependent electrical advance drive prevents overload of motor and gear and excludes compactions of the material by an optimum adaptation of the advance drive speed to the bulk material.

The outlet chute arranged centrally in the silo axis is equipped with a level indicator which switches off the installation in case of overfilling of the outlet chute. All working electrical parts rotate with the screw and will wired through the central electrical rotary transmission

Discharge Capacity

0 - 400 m3/h

Advantages

- High availability with very robust construction

- Continuous bulk material feeding over the whole silo cross section

- Easy assembly and maintenance