Rembe Q-Rohr-3

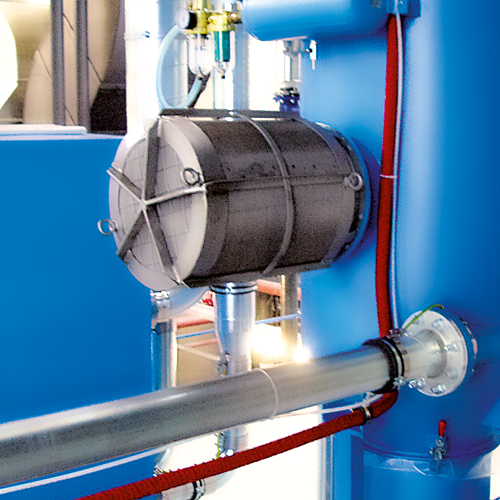

The patented REMBE Q-Rohr®-3 consists of a special stainless steel mesh construction and an integrated REMBE bursting disc. An integrated controller keeps the plant personnel informed about the full operation.

In case of emergency, flames are extinguished and pressure and noise are reduced to negligible levels. No burned or unburned dust passes through. Even the surface temperature (<90 °C / 194 °F) is cooled down to a minimum.

The latest generation of indoor explosion vents from the inventors of 'flameless venting' guarantees indoor venting without any flame and dust propagation.

Free explosion venting of a 5 m3 test vessel with metal dust.

Safe indoor explosion venting of metal dust applications with Q-Rohr-3-6T/6T-AL.

During conventional explosion venting, flame propogation as well as shock waves are only permitted to be directed into safe areas. However, those effects could lead to catastrophic consequences for anyone who is located in immediate vicinity or surrounding areas.

Q-Rohr®-3 is the only system in the world that is approved for deployment in Zone 22 according to VDI-3673, EN 14797, DIN EN 16009 and NFPA 68 and certified by FM Global. Insurance companies across the globe recognize the Q-Rohr®-3 as a safe system for flameless explosion venting.

Indoor explosion venting with flame absorber and dust retainer

The Q-Rohr®-3 explosion protection system is a proven reliable product. It has been designed and engineered following extensive research and development, culminating in the most innovative and efficient flameless venting product on the world market today.

The consistent demand from our customers is the need for a protection system where the flame and dust distribution can be limited to a point where the system can be kept indoors. The Q-Rohr®-3 has been designed with customer driven criteria such as: zero maintenance, unlimited lifespan, huge reduction in the generated temperatures and effective dust retention. The Q-Rohr®-3 has been proven to meet all of those demands.

Proven safety for equipment in any location

With Q-Rohr®-3, difficult to access machines or facilities located amidst production halls can be quickly, simply and safely vented, without cost-intensive, space issues and time-consuming reconstruction. When deploying this maintenance-free protection system: A purely passive solution; no additional operating costs are incurred.

The most economical solution

In a thermographic investigation of a dust explosion, it was recorded that when using a Q-Rohr®-3 there is a huge reduction in the temperatures generated. REMBE’s Q-Rohr®-3, the latest generation of indoor explosion vents from the inventors of 'flameless venting' guarantees indoor venting without any flame and dust propagation. Furthermore, the Q-Rohr®-3, ATEX- and FM approved, is maintenance-free, negating operational costs, ensuring efficient, optimum production and thereby offering the most economical solution. After investing in the Q-Rohr®-3, a return on investment will be noticed within only a few weeks.

Q-Rohr®-3 cools it down

The Q-Rohr®-3 system is the only indoor explosion device that meets the NFPA codes and is approved in accordance with EU regulations (ATEX). It consists of an integrated REMBE bursting disc which vents the explosion wave in a controlled manner within the Q-Rohr®-3 assembly. Flame gases with temperatures higher than 500 °C (2,732 °F) are cooled down to less than 90 °C (195 °F) via energy transfer within the specially developed stainless steel mesh filter inlet. This reduces the expanding gas volume as it extinguishes the flame.

After explosion immediately reusable

Dust retention is guaranteed by the mesh filter ensuring that no burnt or unburnt dust particles pass through the Q-Rohr®-3 assembly. Additionally, the pressure rise and increased noise level associated with free vented explosions are massively reduced to negligible levels. After an explosion event the Q-Rohr®-3 is reusable immediately after cleaning and replacement of the REMBE bursting disc assembly.

Component

Indoor Explosion Vent

+ Flame Absorber

+ Dust Retainer

Applications

- Dust explosion endangered facilities

- Filters, dryers, mills, cyclones etc

- Dust applications

- Gas applications

- Hybrid applications

Photo Gallery

Technical Data1

- Approval:

- IBExU11ATEX2152 X

- Certification:

-

- VDI-3673

- EN 14797

- DIN EN 16009

- NFPA 68

- FM Global

- Patents:

-

- DE 38 22 012

- US 7,905,244

- PStat:

- 0.1 bar @ 22 °C

- Pred:

-

0.1 - 2.0 bar

- ≤ 0.5 bar (silicone dust)

- ≤ 0.5 bar (iron dust)

- ≤ 0.5 bar (steel dust)

- ≤ 0.5 bar (aluminum dust)

- KSt-value:

-

- ≤ 400 bar x m/s (dust)

- ≤ 100 bar x m/s (gas)

- ≤ 300 bar x m/s (hybrid mixture)

- ≤ 200 bar x m/s (silicone dust)

- ≤ 200 bar x m/s (iron dust)

- ≤ 200 bar x m/s (steel dust)

- ≤ 300 bar x m/s (aluminum dust)

- Temperature:

- -10 °C to +230 °C

Technical Drawing2

- Height:

- 600 - 2,200 mm

- Weight:

- 28 - 529 kg

- Diameter:

- Ø 410 - 1,010 mm

- Vent:

- Ø 200 - 800 mm

Design Characteristics

The patented REMBE Q-Rohr®-3 consists of a special stainless steel mesh construction and an integrated REMBE bursting disc. An integrated controller keeps the plant personnel informed about the full operation.

In case of emergency, flames are extinguished and pressure and noise are reduced to negligible levels. No burned or unburned dust passes through. Even the surface temperature (<90 °C / 194 °F) is cooled down to a minimum.

- Available from 8" up to 32" (DN 200 up to DN 800).

- Unique modular stainless steel construction.

- Re-usable quenching chamber made of a special stainless steel mesh filter.

- Multilayered stainless steel dust filter with pressure absorbing properties.

- Integrated bursting disc with signal unit and gasket.

- Bursting discs are also available in aseptic, sanitary and sterile designs.

- Electronic operational and alarm display.

- ATEX and FM type-tested and certified.

- Suitable for full vacuum.

- Special design for up to 600 °C (1,112 °F).

- Sanitary cover keeps the outside clean.

Organic Dusts

Flame gases reaching temperatures of up to 1,500 °C (2,732 °F), are instantaneously cooled down via an energy transfer within the specially developed stainless steel mesh filter inlet.

Thus, the emergent resultant gas volumes are reduced and the flames extinguished. At the same time, the typical rise in pressure as well as the noise level associated with an explosion can be reduced to a very low harmless level. The special filter design prevents the escape of the majority of any burnt or unburnt dust particles.

After an explosion, the Q-Rohr®-3 can be cleaned locally and the bursting disc replaced, making Q-Rohr®-3 ready for use again, with the minimum of loss of production.

The optional sanitary cover keeps the Q-Rohr®-3 clean on the outside.

Metal Dusts

Flame gases with temperatures up to 3000 °C arising in the event of a metal dust explosion are cooled down to a negligible level by means of energy transfer in the patented special stainless steel filter. The leaking gas volume is reduced and the flames are extinguished. At the same time the increase in pressure and the noise pollution, both signs of an explosion, are considerably decreased. The design of the specially developed stainless steel mesh filter guarantees dust retention and non-penetration of burnt or unburnt dust particles. This technical advantage prevents the risk of a secondary explosion when compared with free explosion venting.

Advantages

- No expensive vent ducts required.

- Process optimised arrangement of machines and facilities.

- Simple, visual inspection instead of regular maintenance costs.

- Engineered and Manufactured in Germany.

- Quality and Certifications.

- Besides quality and reliability, REMBE provides environment-friendly technologies and manufactured in accordance with international directives and guidelines.

- All REMBE protection systems and devices are certified in accordance with ATEX 94/95EG and NFPA. Each individual batch (lot) is manufactured and tested in compliance with the requirements of EN 14797. Individual test certificates are supplied in accordance with EN 10204-3.1.

- Data provided are approximate values. Please refer to the latest brochure for the exact values.

- Technical drawing is for illustration of dimensions. It does not represent the actual appearance. Please refer to the site's images as reference.