Rembe Q-Box II

In-house walking and transport routes, streets or adjacent buildings often present a problem for conventional, open explosion venting.

The Q-Box II flame-reduced explosion vent can be used to great effect either outdoors or indoors. When used indoors, it dispenses with the headaches of position complex, cumbersome and expensive vent ducting.

The Q-Box II provides low pressure resistance, effectively eliminating flame and heat emissions, and thereby allowing easy indoor installation and positioning of relevant machinery.

Explosion venting with the Q-Box II, no escaping flames.

The basis of development for the Q-Box II: Heat flow and dispersal analysis as the rupture disc membrane opens into the Q-Box.

Flamebreaker Q-Box II

The Q-Box II flame-reduced explosion vent can be used to great effect either outdoors or indoors. When used indoors it dispenses with the headaches of positioning complex, cumbersome and expensive vent ducting.

The Q-Box II providing low pressure resistance, effectively eliminates flame and heat emissions thereby allowing easy indoor installation and positioning of relevant machinery.

Rectangular connections of the Q-Box II complement the dimensions of the standard Bursting panels thus allowing retrofitting of Q-Box II for existing installations.

Available in two standard sizes Q-Box II offers the best possible solution and the perfect safety system for indoor devices such as elevators when compared to often poorly designed and inefficient venting ducts.

Component

Indoor Explosion Vent

+ Flame Absorber

Applications

- Dust explosion endangered facilities

- Filters, elevators, cyclones and silos

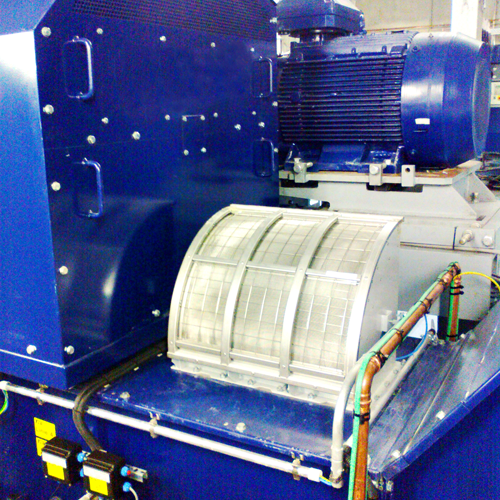

Photo Gallery

Technical Data1

- Approval:

- BVS 06 ATEX H 028 X

- Certification:

-

- EN 14797

- VDI-Guidelines 3673

- EN 14491

- NFPA 68

- Patents:

- U.S. patent pending

- PStat:

- 0.1 bar @ 22 °C

- Pred:

- ≤ 0.5 bar

- KSt-value:

- ≤ 200 bar x m/s

- Temperature:

- -30 °C to +180 °C

Technical Drawing2

Integrated REMBE-bursting disc with signaling and flange seals, also in aseptic, sanitary and sterile designs

Layers of stainless steel flame arrestser with a dust reduction effect.

Junction box for operational and alarm displays.

Option 1:

- Height:

- 500 mm

- Depth:

- 305 mm

- Width:

- 610 mm

- Weight:

- 28 kg

Option 2:

- Height:

- 780 mm

- Depth:

- 586 mm

- Width:

- 920 mm

- Weight:

- 77 kg

Design Characteristics

- Standard Sizes: 305 x 610 mm and 586 x 920 mm.

- Multilayer stainless steel flame absorber mesh enabling dust retention effectiveness.

- Integrated bursting panel with signalling and flange seals.

- Electronic operational and alarm displays.

- ATEX type-tested and certified.

- Bursting panel is also available in aseptic, sanitary and sterile designs*.

- Sanitary cover keeps the outside clean*.

The Q-Box II captures flames and heat during explosion venting; allowing easy indoor and outdoor installation and positioning of relevant machinery. Manufacturing equipment of low sturdiness and with large venting area requirement is cost-effectively protected from the aftermath of an explosion.

The rectangular cross section complements the dimensions of standard bursting panels, making the protection system suitable for retrofitting existing installations. This protection system is maintenance-free, negating operational costs.

The Q-Box II is the perfect safety system for indoor devices, such as elevators, and when compared to cost-intensive venting ducts, the Q-box II is the true economical alternative.

Advantages

- Ideal when retrofitting existing installations.

- Indoor / outdoor deployment.

- Minimization of safety zone space in reference to venting ducts = yielding more efficient utilization of operating space.

- Engineered and Manufactured in Germany.

- Quality and Certifications.

- Besides quality and reliability, REMBE provides environment-friendly technologies and manufactured in accordance with international directives and guidelines.

- All REMBE protection systems and devices are certified in accordance with ATEX 94/95EG and NFPA. Each individual batch (lot) is manufactured and tested in compliance with the requirements of EN 14797. Individual test certificates are supplied in accordance with EN 10204-3.1.

- Data provided are approximate values. Please refer to the latest brochure for the exact values.

- Technical drawing is for illustration of dimensions. It does not represent the actual appearance. Please refer to the site's images as reference.