SHW Eccentric Frame

Eccentric frame can be used for the reception area of bulk materials delivered externally in your plant. Bulk material can be brought in the further storage or transport process.

The equipment can also be used for the discharge of bulk materials from different types of silos.

The ideal discharge unit for both wet and dry bulk materials. For circular silos, there is a rotating and eccentric movement of the rotary wheel. For rectangular silos, the frame moves eccentrically.

Component

Reception Component

Discharge Component

Applications

- Bulk material reception

- Bulk material intermediate storage

- Bulk material repartition along the process chain

- In Combination with SHW-relief systems prevention of stable bridge buildup

- Sewage Sludge:

- Slow flowing, compacts, abrasive

- Paper Waste:

- Fibrous, compacts / blocks

- Paper Sludge:

- Fibrous, compacts / blocks

- Dry Flakes:

- Compacts

- Sander Dusts:

- Compacts

- Shredded Waste Wood:

- Blocks, abrasive

- Wood Chips:

- Blocks, abrasive

Photo Gallery

Technical Data

- Drive:

- 2.2 - 7.5 kW

- Dimensions:

- Circular:

- 3,000 mm, 4,000 mm, 5,000 mm diameter

- Rectangular:

- 2,000 mm x 3,000 mm, 3,100 mm x 4,000 mm

- Optional intermediate sizes available.

- Weight:

- approx. 2,500 kg

- Controls:

- Function, optional storage temperature

- Wear:

- As an option, specially tailored to the application and the bulk material, for example different stainless steels, Hardox, wear protection welding, Infinite Shield (ceramic)

- Execution:

- CE declaration of conformity

ATEX: standard no ex-qualification

Alternatives:

Inside: Zone 22 /

Outside: No Zone (EX II 3/-D)

Technical Drawing

- Rectangular execution:

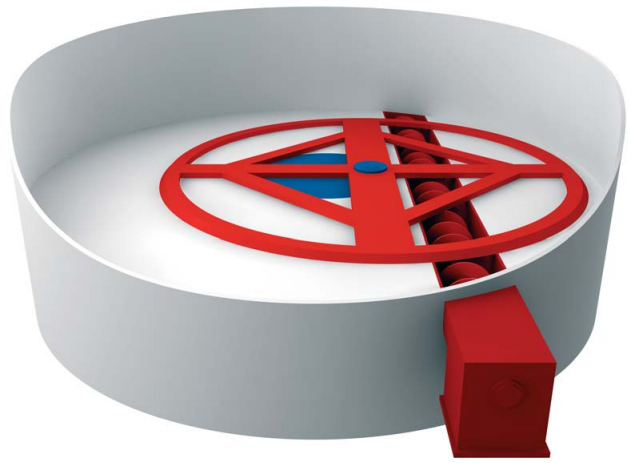

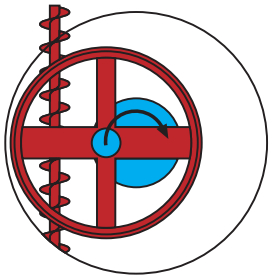

- Circular execution:

Design Characteristics

- Space-saving construction

- Robust construction

- Circular or rectangular design

The eccentric frame can be used both in rectangular silos and in cylindrical silos.

Rectangular silos:

- Dimension:

- from 1.5m x 1.5m up to 4m x 5m

- Maximum:

- up to 8m for dry flakes,

up to 5 m for wet flakes

Cylindrical silos:

- Diameter:

- from 1.5m up to 5m

- Maximum:

- up to 10m for dry flakes,

up to 5m for wet flakes

With the eccentric frame you can discharge all free flowing bulk materials with a density of <400 kg/m³ which do not compress under pressure as well as municipal sludge.

The drive of the eccentric frame and the screw drive can be adjusted via frequency converter.

The eccentric frame is driven via an eccentric disc where the wedge-shaped outside of the frame slides under the bulk material and transports it to the inside and into the directional discharge system. The silo can be filled from above (up to 4 screw conveyors).

The advantages are evident: high metering exactness, low required space and up to 50 % lower driving power compared to conventional systems.

Discharge Capacity

10 - 100 m3/h per discharge screw

Advantages

- Low building costs (Installation height)

- Low life-cycle-costs

- Mechanical design easy to maintain

- Up to four discharge screws combined in one silo